Speaker Enclosure – Acoustic Suspension

A speaker enclosure can be made in several different ways, using different types of materials.One of the easiest ways of making a custom sealed speaker enclosure is by using 3/4” MDF board and automotive carpet.

I’m getting a little bit ahead of myself here, let me start by saying that making a speaker enclosure is not just about building a box and covering it with fabric. Before you start thinking about design and aesthetics you need to start with space and size of the box.

Space and Size of the Speaker Enclosure

Amplifiers, sub-woofers and especially woofers all take up a lot of space in the vehicle. If you want more sound from the speaker, you will have to give up more space for your speaker enclosure. So before you buy speakers and start building a speaker enclosure make sure you have the space needed to fit the size of woofers you will be using. Measure the area in the car that you are willing to give up for your speaker enclosure and don’t forget space for amplifiers and the width of the wood used to make the speaker enclosure.

Specs of the Speakers

Once you have the space figured out, the audio dealer can recommend the best speakers for the sound you want to have. They will also have specs for the speakers themselves that will help you figure out the size of cut outs you need to make for the speakers and even recommended dimensions for the box itself. If you already have the speakers you can go to the manufactures website to get the specs you need to build the best speaker enclosure for your car.

Design of the Speaker Enclosure

There are so many different configurations for a speaker enclosure. Here we are focusing on the acoustic suspension or sealed box design. The sealed box configuration can be designed in many different shapes and sizes to custom fit your vehicle.

There are so many different configurations for a speaker enclosure. Here we are focusing on the acoustic suspension or sealed box design. The sealed box configuration can be designed in many different shapes and sizes to custom fit your vehicle.

Drawing Your Design

Draw out your design on graph paper to get a good idea of how it will be incorporated into the area you’ve specified for it. Graph paper helps because the squares can represent inches or feet of space so when you draw it out it will give you a sense of the amount of wood and fabric you will need for the job. If you make a lot of speaker enclosures in different shapes, a computer program like Leap will definitely be helpful.

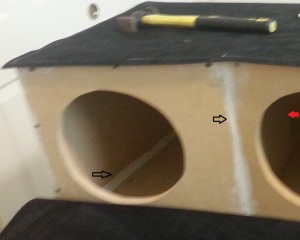

Planning Chambers

Each speaker should have its own chamber, I know there are pre made boxes out there that use one chamber for multiple speakers but for the best sound in a custom box you need to have separate chambers so that the speaker vibration does not interfere with the sound.

Building the Box

The wood

The wood has to be solid. This is one of the most important things to know about making your own custom speaker enclosures. You have to pay close attention to the way it is being put together. If there is any portion of the box that does not fit together well, air and most importantly sound will escape through this gap in a less fluid frequency causing increased noise and rattling. If your box is solid and you are still hearing a lot of rattling, you need to check your speakers to make sure you don’t have a blown or damaged speaker on your hands.

The wood should be at least ¾” MDF board. I recommend MDF because it is high density and not as porous as particle board.

Screws/staples

Use drywall screws to put the box together, one screw at least every 4”, don’t forget to pre-drill your holes. Counter sink the screws and cover the heads with silicone or weather stripping to make sure no air escapes from the holes and to provide a smooth surface all the way around. If you have a pneumatic stapler, you can staple the box together a lot faster but make sure to apply wood glue to the different pieces so that it holds together well.

Sealing the Speaker Enclosure

Once the box is put together apply silicone along all wall joints including interior chamber walls, and screwed or stapled areas to make an airtight seal.

Covering the Speaker Enclosure

Once the box is built and sealed areas have been allowed to dry you can cover the speaker enclosure with foam and fabric or with carpet, depending on the style you are going for. Using upholstery adhesive, spray the box and the back of the carpet, laying it down in small sections to make sure you have a smooth coverage and a good bond. If you are using fabric and foam you will glue the foam to the box first and then glue the fabric to the foam working in sections like you did with the carpet.

If you want a more custom look that requires sewing or you have a complex design that will be complicated to cover you can make the box and take it to a professional upholstery shop to cover for you. If you want a custom speaker enclosure and don’t want to mess with making the box or covering it most upholstery shops that specialize in automotive interiors can make you a quality box for you.